- sales@hexigon.in

- +91 9824091132

- +91 8200923790

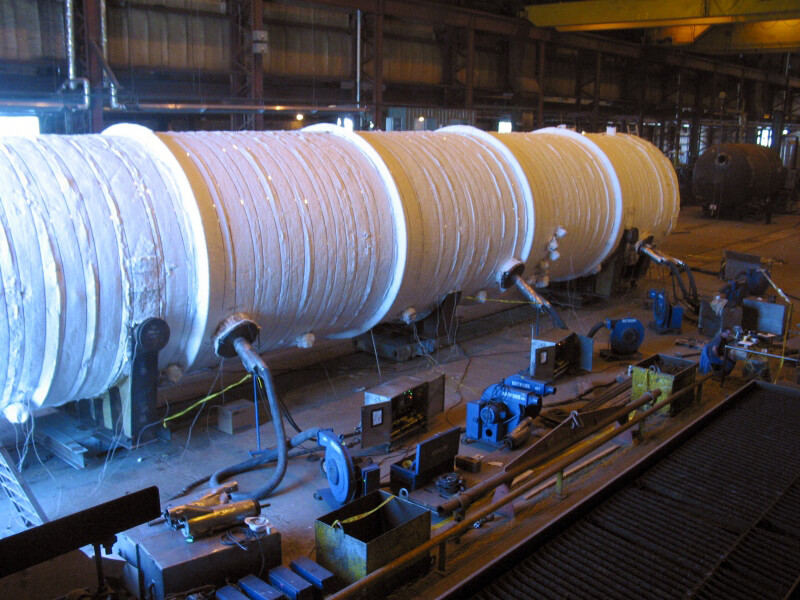

Post Weld Heat Treatment (PWHT) by External Oil Firing is a proven on-site heat treatment technique used for large, heavy, and complex welded components where electrical resistance heating is not practical. In this method, a temporary modular furnace is constructed around the job, and controlled heating is achieved using diesel/oil-fired burners to uniformly raise the temperature to the specified PWHT range.

External Oil Firing PWHT is widely adopted for shutdown and turnaround projects in refineries, petrochemical plants, power stations, and heavy fabrication yards, providing furnace-like heating performance at site.

PWHT using External Oil Firing is performed in compliance with:

ASME Section VIII Div. 1 & 2

ASME B31.1 / B31.3

API 650 / API 653

NACE MR0175

Customer-specific specifications

Suitable for very large and heavy components

Provides uniform heating similar to a permanent furnace

Ideal for thick-wall sections and deep weld penetration

Effective for multiple weld joints in a single setup

Faster heating rates compared to resistance methods for large jobs

Highly cost-effective for shutdown and turnaround projects

Accurate temperature monitoring with full data recording

Precision-driven PWHT and refractory dryout services executed to international standards

At Hexigon Private Limited, we deploy carefully selected, high-quality equipment to ensure precise temperature control, uniform heat distribution, and full compliance with international PWHT standards.

Nichrome heating elements embedded in ceramic beads provide flexible and uniform heating.

Advanced multi-zone temperature control systems (typically 6 to 12 zones) manage heating rates, soak temperatures, and controlled cooling cycles

Calibrated thermocouples are securely welded directly onto the component to measure true metal temperature.

High-grade ceramic wool or rock wool insulation blankets are used to minimize heat loss and maintain uniform temperature distribution.

Heavy-duty power cables, splitters, connectors, and safety accessories provide secure electrical connections between heaters and control units.