- sales@hexigon.in

- +91 9824091132

- +91 8200923790

Post Weld Heat Treatment (PWHT) is performed to relieve residual stresses, reduce hardness, and enhance the mechanical properties of welds. The Electrical Resistance Heating Method is one of the most widely used on-site PWHT techniques due to its accuracy, portability, and suitability for large structures.

PWHT using electrical resistance heating complies with:

Congue accumsan vulputate nulla sed porta adipiscing est erat habitasse fringilla maecenas purus sapien pretium parturient tellus dis interdum nostra amet

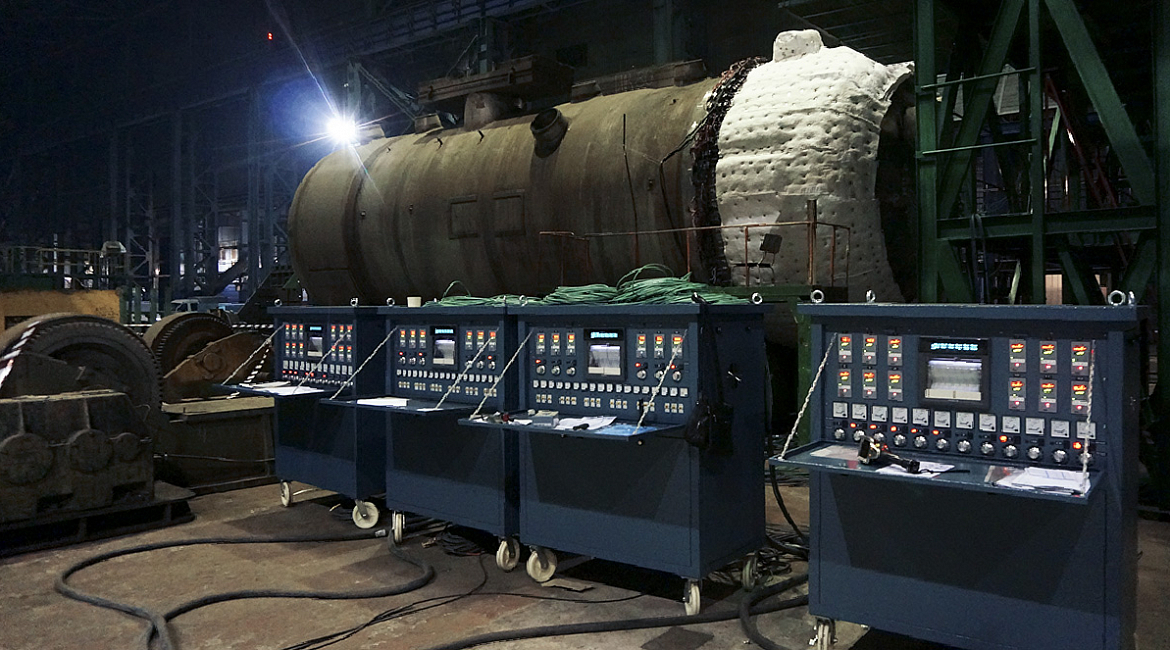

Electrical PWHT uses high-quality, field-proven components designed to deliver precise, uniform, and controlled heat treatment.

Nichrome wire embedded in ceramic beads, flexible and suitable for pipes, vessels, and complex shapes.

Multi-zone controllers (commonly 6–12 zones) manage ramp rate, soak temperature, and cooling

Welded on the job to measure accurate metal temperature

Ceramic wool or rock wool to retain heat and ensure uniformity.

Connect heaters to power sources safely